Eddy Current Testing Systems & Applications

Salem NDT designs and manufactures a variety of eddy current testing machines that help you perform inspections faster and verify complex geometries without comprising accuracy.

Eddy Current Inspection Systems

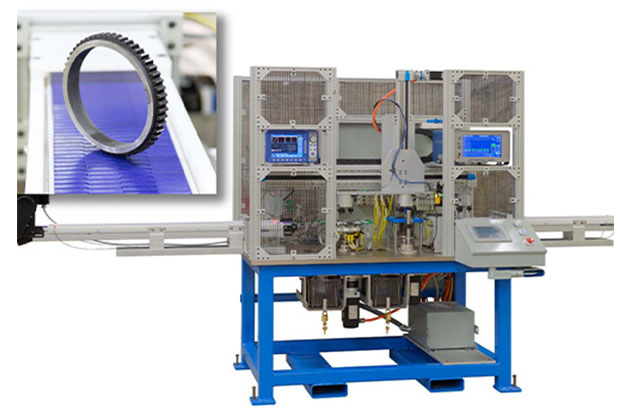

Stand Alone ECT

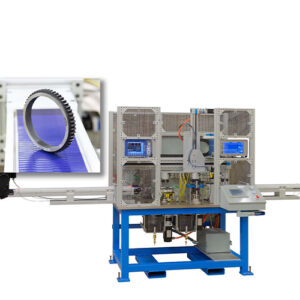

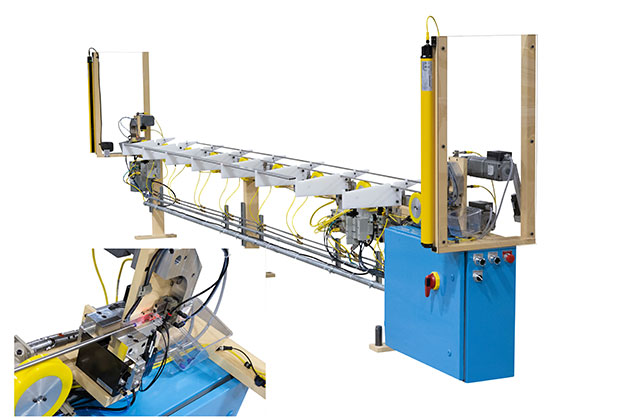

Small Diameter ECT

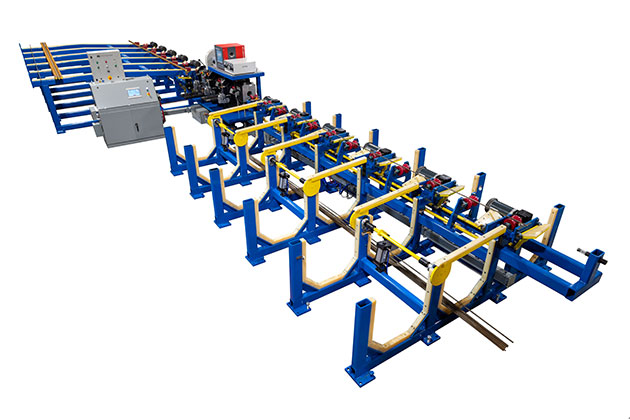

Large Diameter ECT

Gear Testing

Nuclear Fuel Rods

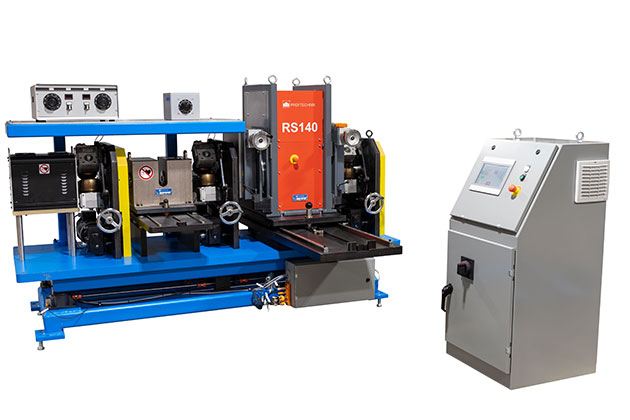

Offline EC Bar Test

Focus on your business & let our team of experts handle the rest.

Eddy Current Systems

Custom Built To Work For You

Make your eddy current inspections faster using an eddy current machine without compromising accuracy. Turnkey systems can be built from one source to your application using a complete line of eddy current testers, instruments, and systems for non destructive testing of metal components.

Salem NDT is dedicated to helping manufacturers avoid huge safety risks by producing custom eddy current inspection machines to test components during the manufacturing process.

Eddy Current Inspection Applications:

Structure Test

Crack, Pore, Grinder Burn Tests

Eddy Current Probes & Coils

Zero Defect Scanners

Eddy Current Sorters

& More

Engineered Safety in Turnkey Testing and Inspection Systems

When you choose Salem Design & Manufacturing, we guarantee that our experience and knowledge in application analysis and testing will deliver a complete inspection solution that provides you with a competitive advantage of having a zero defect part inspection capability.

Inspection Systems using Eddy Current

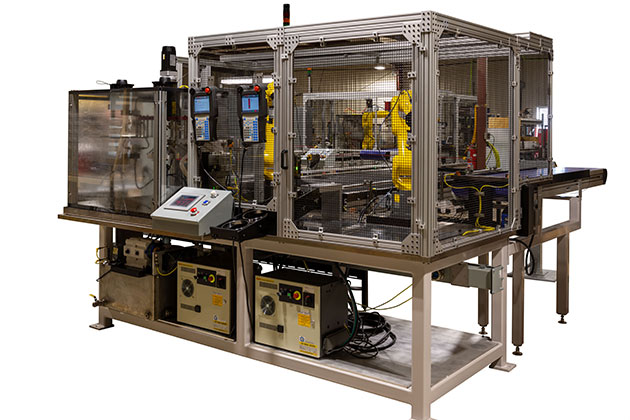

Uni-Versal™ Robotic Eddy Current Testing Machine

CNC Eddy Current Machine

Transmission Clutch Inspection Machine

Robotic and Gantry Features

Uni-Versal™ EC Machine

Trust Salem NDT as Your Expert for Custom Eddy Current Inspection Systems

Salem NDT offers Non-Destructive Testing solutions with an experienced and expert team who can assess and provide on-site installation, repair and support services. Contact us for a quote or to speak with our expert team.