Eddy Current Heat Treat Verification Solutions

Advanced nondestructive eddy current heat evaluation testing for material structure validation

Heat Treat Verification and Crack Detection Machines

Eddy Current Heat Treat Validation: Testing Internal Features

Eddy current is a proven testing process used to validate the material structure of conductive components. The system is equipped with eddy current probes and sensors that will identify alloy compositions, check for heat treat conditions and find crack or flaw defects.

Even the strongest brands need to inspect 100% of their parts. Check out some of Salem NDT’s eddy current heat treat and material structure testing sytem design capabilities below.

How Eddy Current Validates Critical Heat Treat Processes

Eddy Current Systems Validate Heat Treatment Process and Includes Crack Testing Verification

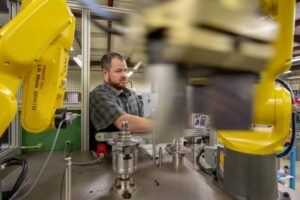

Eddy current stand alone systems are effective evaluation solutions for non destructive testing to detect deviations from expected signatures and patterns without damage to the component. Each works independently so that your quality control testing is both reliable and flexible enough to move into any high volume production lines.

The stand alone testing systems built by Salem NDT integrate NDT kits that are designed to be low-cost and able to work in a stand-alone way. Eddy current testing systems have a wide range of functions and applications. This versatility enables you to integrate the inspection machine to fully inspect parts and materials into your production line.

Salem NDT designs and builds a wide range of cost-effective eddy current NDT Systems that are independent of your production line and used to test and evaluate the properties of materials, parts and products without affecting the integrity of the component.

Find out which areas we can assist you in by visiting some of our stand alone non destructive testing systems.

High Temperature Eddy Current Testing

- Comparative tests

- ECT validates material structure

- Production sampling of parts

- Heat treat testing of internal failures

Get a Personalized Estimate For A Custom Built Hardness Testing Machine

With such broad capabilities, Salem Design and Manufacturing partners with corporations to custom design and build non-destructive testing machines that can sort, test and inspect parts to a degree not easily achieved with human or other optical inspection systems. Fill out the form below and we’ll get back to you to get more details.